Waste-to-Energy Sorting

MSS Optical Sorters have what it takes to automatically sort even the “dirtiest” of waste-to-energy material streams. MSS provides solutions for the most efficient front-end separation systems for waste to energy facilities that have to meet even the most demanding performance objectives. Our recycling technology is field-proven and, used in combination with mechanical processing and separation systems, able to generate a commodity with consistent calorific value for your WTE application or remove prohibitive contaminants (PVC) from the stream automatically.

Ultra-Efficient Separation, Powerful Optical Sorters

There are several areas in a WTE processing facility where MSS optical sorters are in a position to provide added value for our customers. The automated removal of PVC and positive extraction of high-calorific materials to produce a WTE commodity stream with consistent calorific value are two of the most used applications.

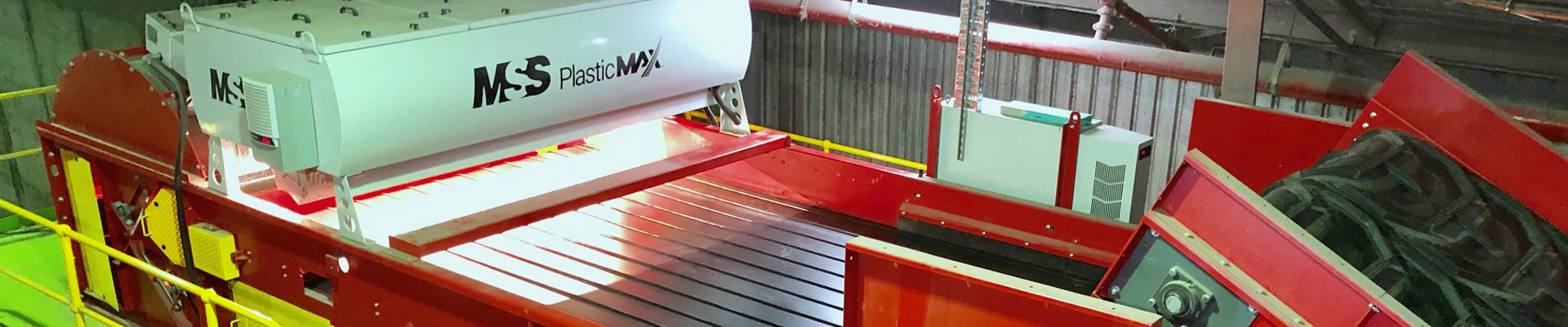

CIRRUS PlasticMax™

PlasticMax™ provides the most accurate separation of all plastic resins in all types of waste management facilities. All PlasticMax™ optical sorters combine high-resolution NIR, color, and metal sensors to accurately sort a wide variety of materials, using advanced algorithms. Our proprietary MaxSelect™ sequential scanning technology provides the best combination of scan rate, number of wavelengths and NIR wavelength range (up to 2,500nm). The integrated ClearLight™ technology provides the best signal-to-noise ratio of any optical sorter in the industry because MSS doesn’t use gratings or light beam splitters.

CIRRUS FiberMax™

FiberMax™ provides operation flexibility and top of the line sensing capabilities to either extract fiber from mixed input streams or separate paper into the various gradesl. The integrated MaxSelect™ technology utilizes patented sequential scanning technology for the highest-definition image possible. ClearLight™ technology provides the best signal-to-noise ratio of any optical sorter in the recycling industry. MSS doesn’t use gratings or light beam splitters, so detectors receive the maximum amount of reflected light possible, allowing for the most accurate detection.

MetalMiner™

Our longest running sensor-based technology! For over 30 years, we have used our proprietary induction-based metal detection technology in many different applications. The latest generation provides maximum sensitivity at low cost and durability. As a stand-alone unit, the MetalSort™ provides for the removal of metal contaminants (ferrous, non-ferrous and stainless) at high efficiency.