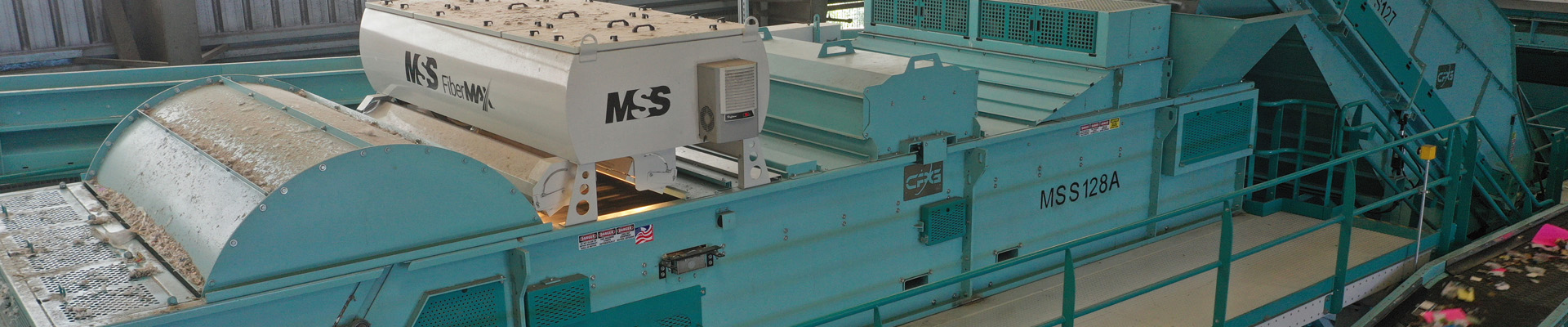

Next-Generation Optical Fiber Sorting Technology

Based on the popular CIRRUS® sensor platform, the FiberMax™ provides operation flexibility and top of the line sensing capabilities. MaxSelect™ utilizes patented sequential technology for the highest-definition image possible. High number of NIR and color wavelengths make it possible to change sort setups by only software programming, no hardware changes required. ClearLight™ technology provides the best signal-to-noise ratio of any optical sorter in the recycling industry. MSS doesn’t use gratings or light beam splitters, so detectors receive the maximum amount of reflected light possible, allowing for the most accurate detection of highly transparent items such as lightweight single-serve PET bottles..

Take Control of Operating Cost and Product Marketability

As the ultimate optical fiber sorting solution for MRFs, FiberMax™ reduces head-count on the Fiber QC line while greatly improving fiber purity for best marketability, reducing exposure to market risks such as “Green Fence” or National Sword.” Operators across the country are seeing quick returns on investment.

The Material Handling Experts

Maximizing material recovery relies on proper material handling. MSS uses high-velocity belt speeds of 1,000 feet/minute (5 meters per second). This enables proper material distribution that results in minimal collateral damage, giving FiberMax™ a competitive advantage over the other sorters. One FiberMax™ does the job of 20 manual QC sorters, averaging 600-800 picks per minute.

Reduce Headcount

Eliminate multiple manual sorters on fiber QC line with FiberMax™ automated sorting. Averaging 600‑800 picks per minute, 1 FiberMax™ does the job of 20 manual QC sorters.

FiberMax™ Sort Efficiency

In an independent 2017 study, FiberMax™ achieved a 96.6% sorting efficiency of flexible plastics packaging (FPP) such as film, bags, pouches, etc. from mixed paper in a commercial single-stream MRF. Over 23,000 pieces of FPP were artificially added to the input material in order to create a “spiked” sample that generated statistically relevant data.

Features

- Near-Infrared (NIR) and color sensors included

- Single-eject or dual-eject setup

- Color touchscreen with remote Ethernet access

- Language selection

- Change recipes by the touch of a button

- Continuous automated internal calibration

- Software license never expires

- 1,000 FPM (5m/sec) belt speeds

- All-metal detector

- Split configuration

- Statistics/QC reports

Applications

- Sort contaminants and OCC from ONP and SRP

- Positively Sort ONP and SRP

- Positively Sort SOP and SWL

Specifications

- Machine width: 1600–2800mm (64”–112”)

- Capacity paper*: 2.0–12.0 ton/hr

- Efficiency*: Up to 98%

- Electricity: 8–12kW

- Compressed air: 100psi / 7 bar

*Actual throughput and performance depends on a number of factors including, but not limited to, input material composition, particle size, bulk density and % of targeted materials.