Metal Recycling Equipment

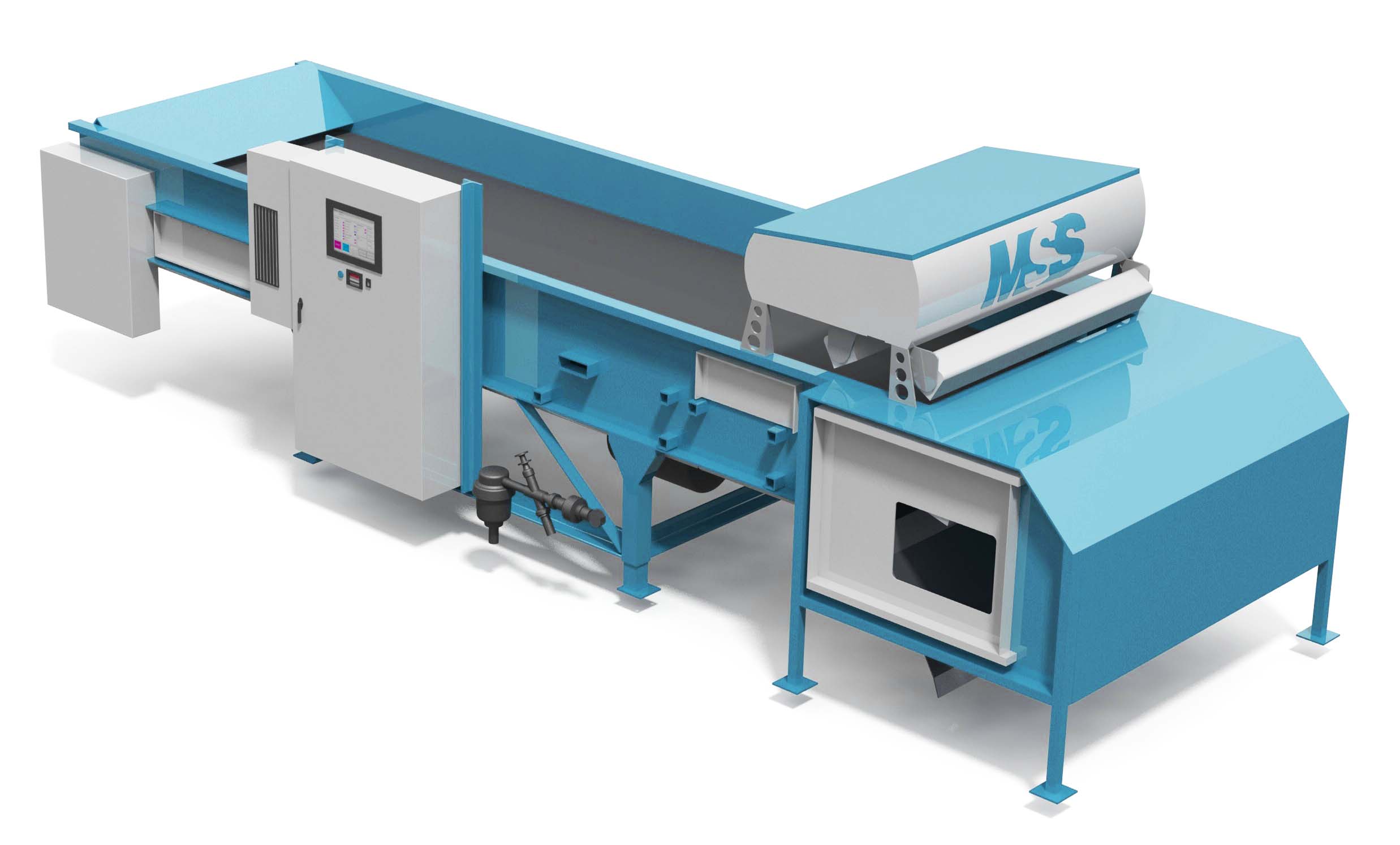

MSS Metal Recycling Technology

Metal recycling has a long history. As early as WWII there were efforts to collectively save and reprocess metals to aid the war effort. Part of the reason for this interest is the ease of magnetically sorting steel. Modern recycling equipment can identify many kinds of metals, although more complex technology is required to separate non-ferrous metals.

Basic metal sorting involves separating ferrous from non-ferrous metals. Ferrous metals contain iron, and are attracted by magnets. This allows iron and steel to be pulled from a waste stream easily. Large pieces of scrap can be moved by cranes fitted with an electromagnet. This type of crude machinery is most often seen at auto salvage yards.

Municipal mixed, or partially sorted, waste streams contain easily identified fractions of ferrous metals and aluminum, mostly from discarded food and beverage containers. In mixed streams, paper is generally removed first leaving metals and plastics. When electric currents are induced across the remaining materials, metals are affected, and plastics are not. This is known as eddy current separation. Most materials recovery facilities now use this type of metal recycling equipment . Even though aluminum is not magnetic, eddy currents can levitate it, allowing plastics to drop out of the process, and the aluminum to be removed.

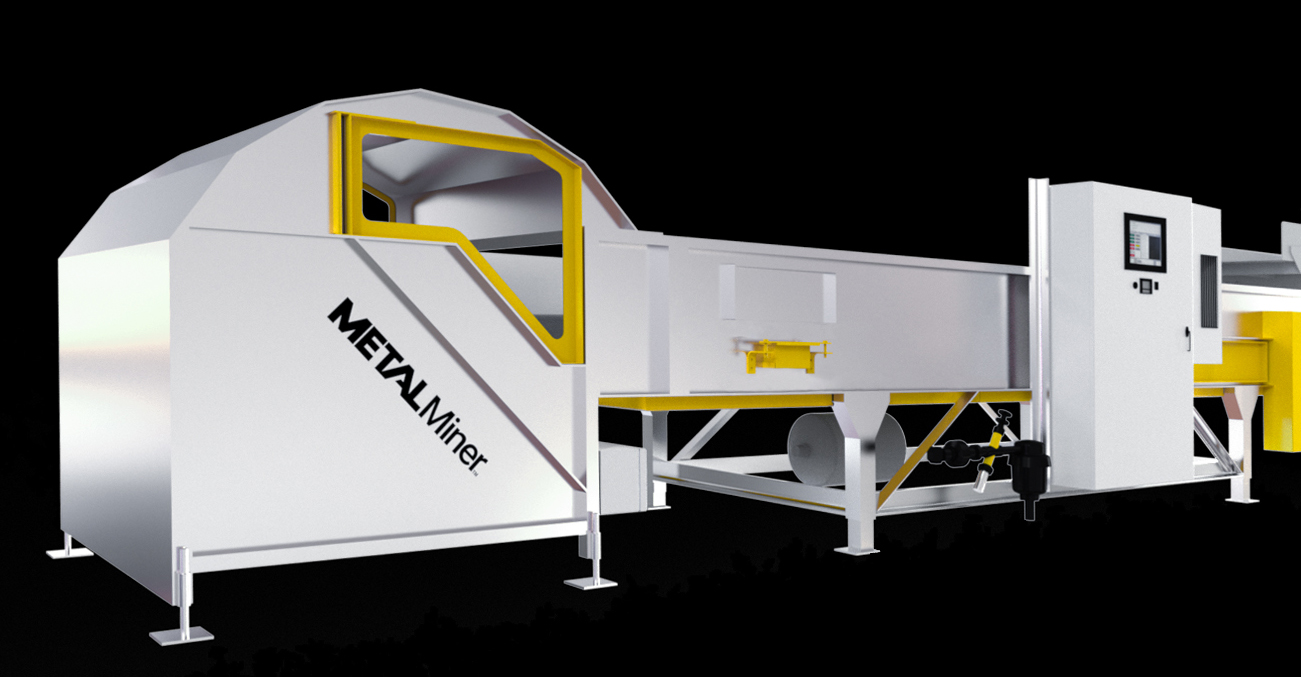

Because of the value of copper, lead, gold, silver, platinum and palladium, if enough scrap can be collected, it becomes economically viable to recover precious metals from electronic waste. This process requires more technologically advanced metal recycling equipment. The use of sensors to identify metals through x-ray and infra-red scanning is becoming more common in large facilities.

Large-scale metal recycling of mixed materials is accomplished best by pre-shredding the items to reduce the size of the pieces. This increases surface area, and helps isolate smaller fractions.

There are three categories of metal sensing processes which are being used or at least studied to improve recovery. These are pyrometallurgy, hydrometallurgy, and biotechnology.

Pyrometallurgical processes heat mixed metals, and separate the fractions in the molten state. This separation takes advantage of the differing melting points of metals.

Hydrometallurgy refers to the application of various chemicals to mixed waste, usually in a water solution. The various controlled reactions with the metals will remove them individually from the slurry.

Another promising method is biotechnology, which recognizes the fact that certain microorganisms will seek out and consume particular metals, which can then be harvested.