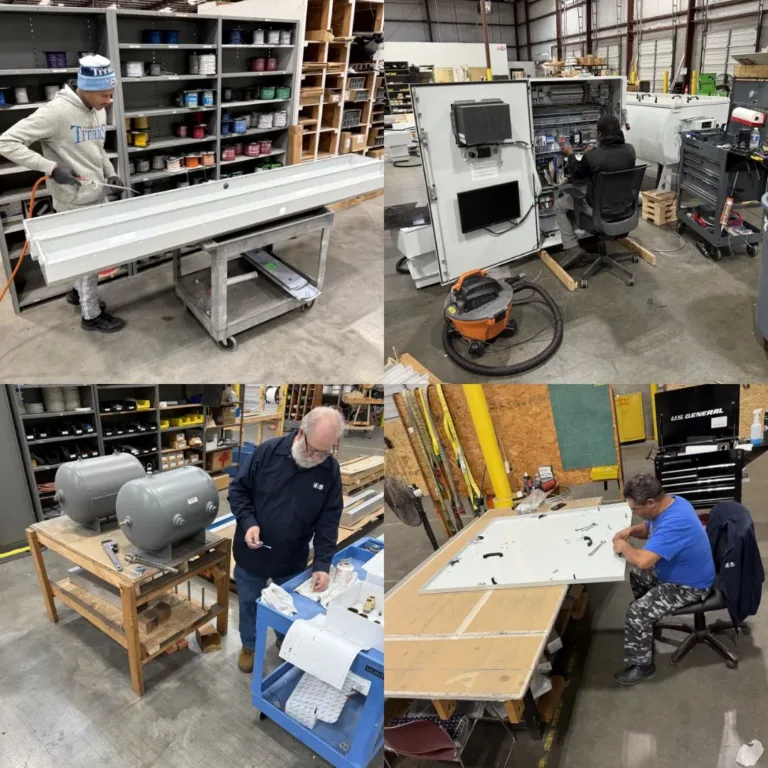

Culture

Ethical. Commitment. Excellence. Teamwork.

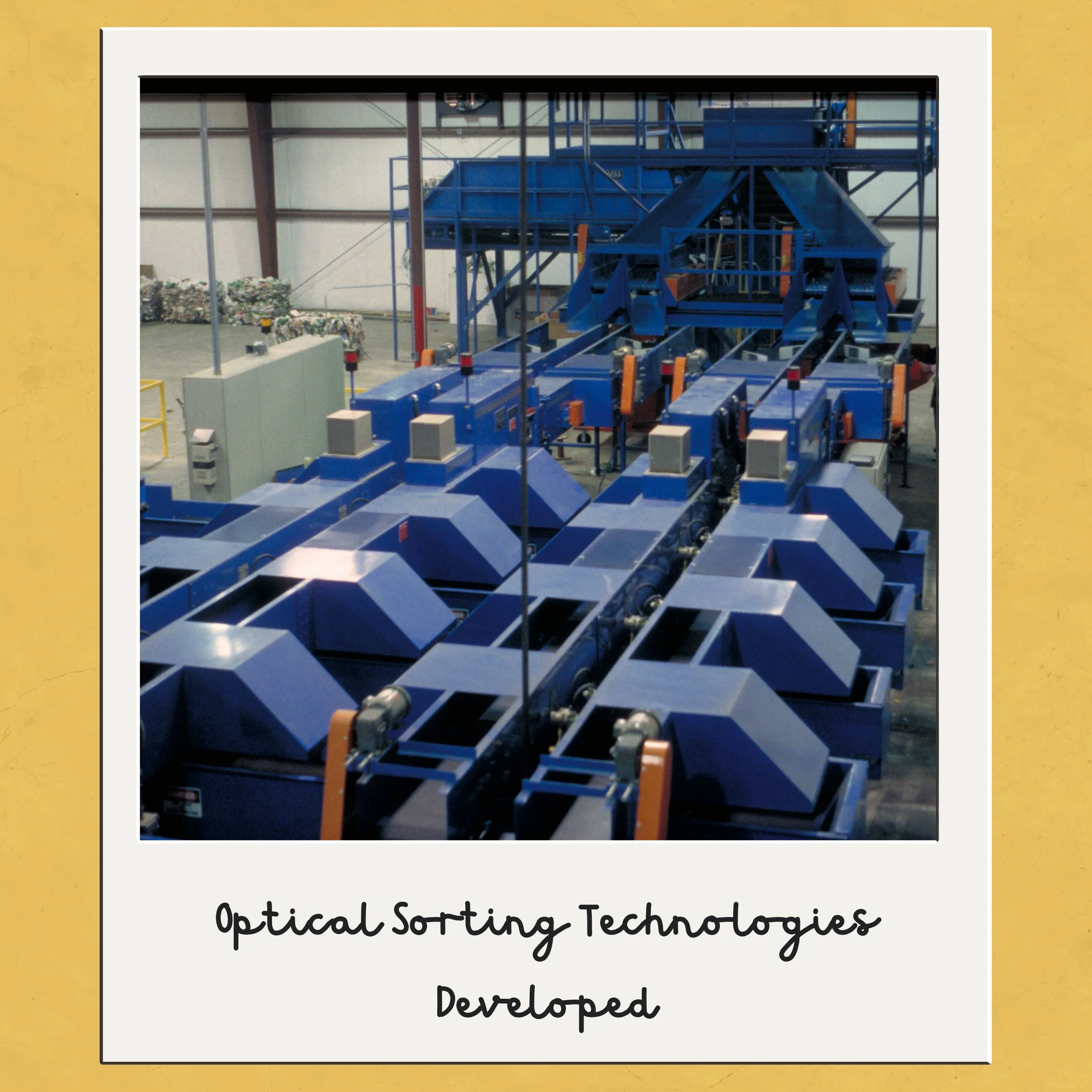

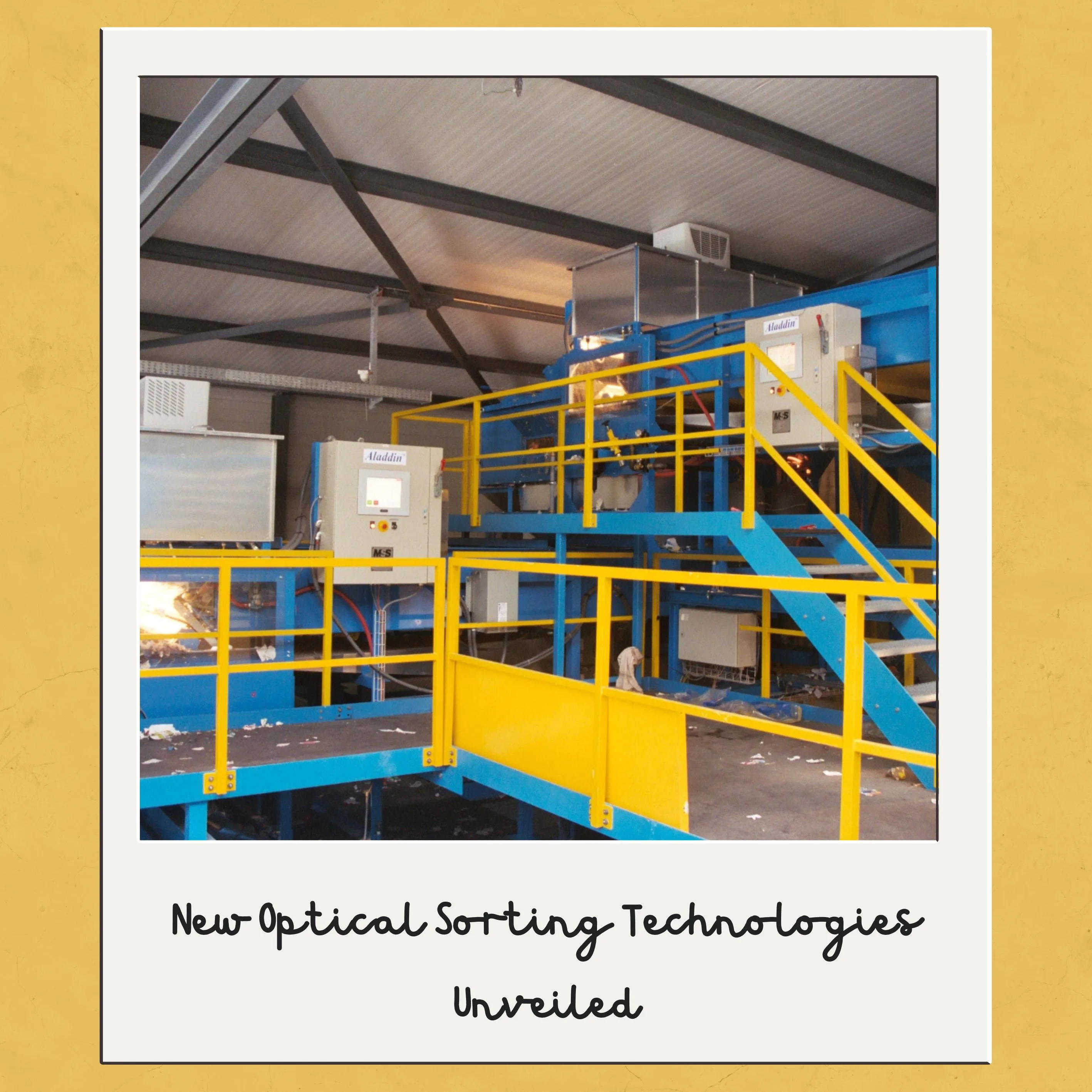

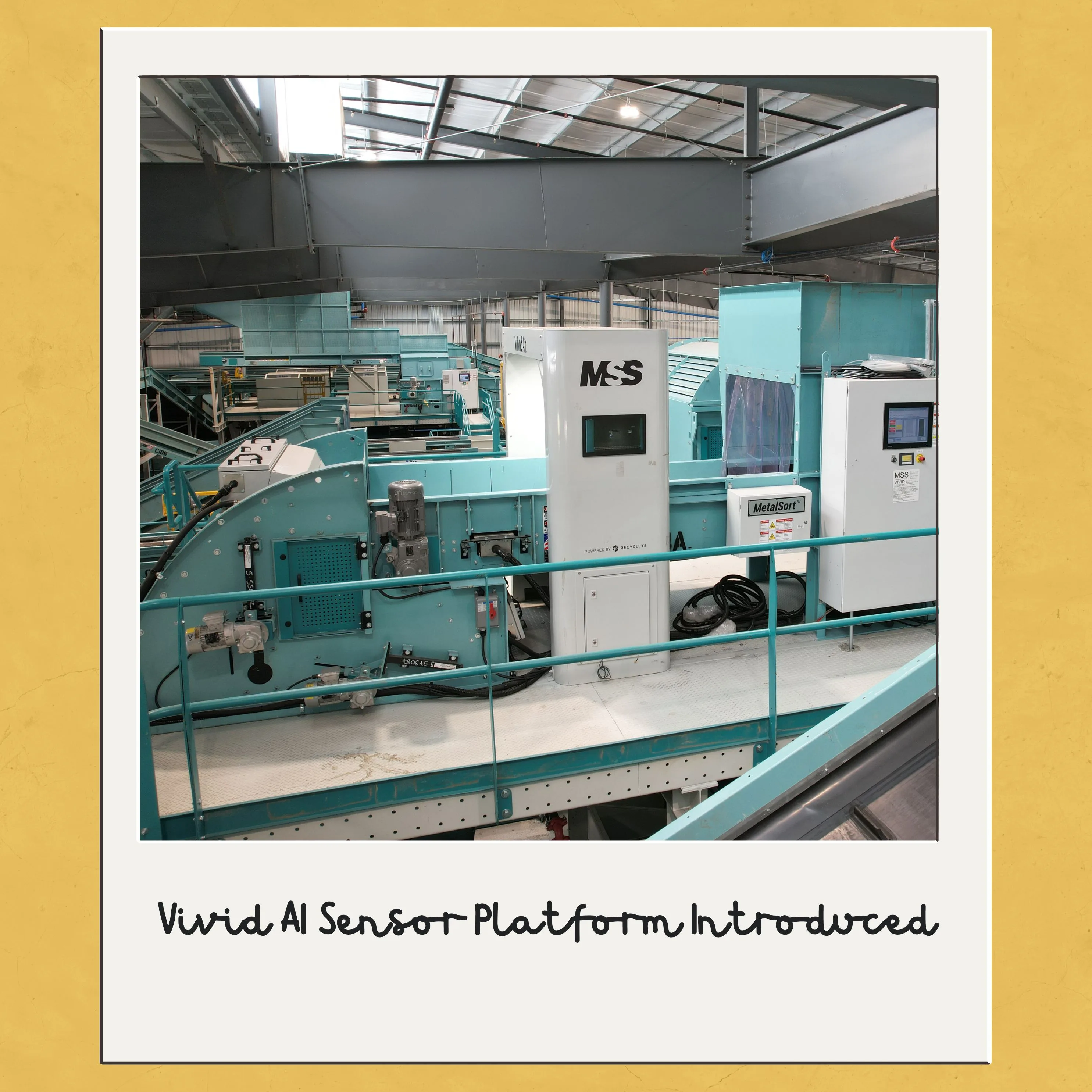

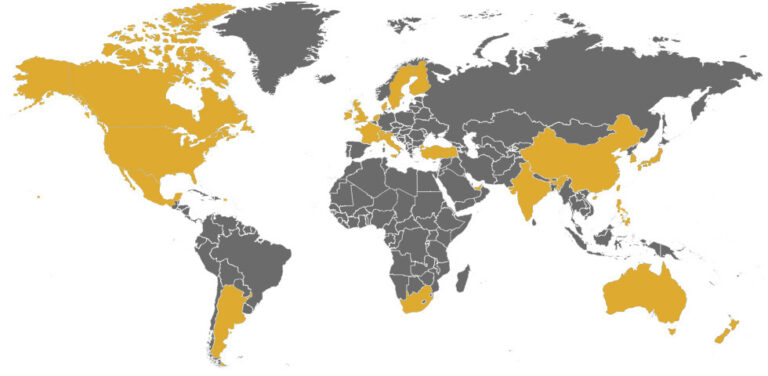

Our company culture is defined by ethical practices, a commitment to excellence, and teamwork. At MSS, Inc., we innovate ultra high-speed optical sorting technology for the waste and recycling industry, ensuring efficient, cost-effective solutions that meet market demands while positively impacting the environment and empowering our clients for the future.