Technology

Commitment to Superior Quality

Our mission is to manufacture exceptional optical sorting equipment at our state-of-the-art facility in Nashville, ensuring the highest standards of quality in every product we deliver.

Our mission is to manufacture exceptional optical sorting equipment at our state-of-the-art facility in Nashville, ensuring the highest standards of quality in every product we deliver.

MSS prides itself in providing automated optical sorting solutions to all sectors of the recycling and waste management industry. Our innovative sensor technologies provide an array of recycling businesses with the opportunity to increase their efficiency, throughput and, ultimately, the bottom line.

We are committed to pioneering advancements in automated sorting technologies for material recovery facilities. Our strategic approach ensures high efficiency, purity, and low-cost recovery, setting new standards for the industry.

We employ a selective sorting concepts, meticulously pairing the right sensor technology, including AI, NIR, color and metal detection, with the appropriate extraction method. This synergetic approach maximizes sorting efficiency, aligning with each facility’s unique requirements.

By utilizing our in-house array of available sensors, we achieve the highest levels of extraction and purity by using our proven positive pressure air jets. All our systems are designed for the fastest belt speeds and widest belts, ensuring readiness for future demands.

Our optical sorting machines replace difficult-to-staff manual quality sorting stations, offering an optimal blend of speed, precision, and cost-effectiveness. This automation elevates the sorting performance, contributing to more streamlined and efficient MRF operations.

Seattle, WA

A CP customer in the Pacific Northwest faced difficulties in achieving the required fiber quality, with 26 manual sorters on two lines unable to reduce ONP contamination below 1–3.

In response to evolving market demands and increasing operational costs, MSS introduced the CIRRUS® FiberMax™, a high-speed optical sorter designed to produce fiber products that meet stringent international standards, such as those set by China.

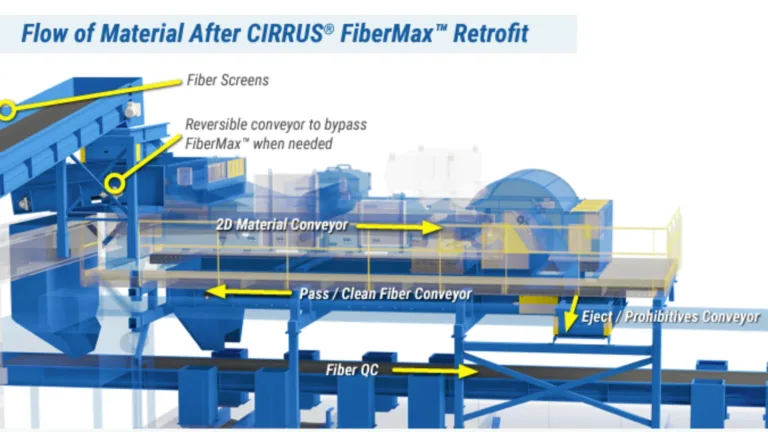

To address these challenges, the facility underwent a strategic retrofit, integrating two MSS CIRRUS® FiberMax™ units on the 2D overs lines from the initial disc screens. This upgrade was executed with minimal disruption to operations.

The FiberMax™ sorters efficiently distinguish and remove non-fiber contaminants, significantly improving fiber quality. As a result, the facility reduced manual labor by 62% and now consistently meets the foreign market requirement of 0.5% ONP contamination.

Post-implementation, the FiberMax™ units demonstrated impressive performance, achieving between 1,000 and 1,500 picks per minute per unit, and handling 10-11 TPH throughput per unit. These enhancements led to a combined sorting capacity of 18,667 square feet per minute.

By ensuring high fiber purity and reducing labor reliance, FiberMax™ offers a robust solution against market risks like the “Green Fence” or “National Sword,” positioning itself as the premier choice for maximizing material recovery with a 96.6% sorting efficiency for diverse fiber products.